The InDesA Virtual Test Bench

A Virtual Concept to accelerate the Product Creation Process

The demands of modern vehicle design require that many components be designed and tested simultaneously. Almost all of these components need to be specifically optimized for their role in the particular vehicle design, and many utilize innovative technology. With little time for construction and testing of physical prototypes, along with the need for fast adaption of components due to changing module and system requirements, there is a compelling case for the introduction of more virtual testing at component level in vehicle development programs.

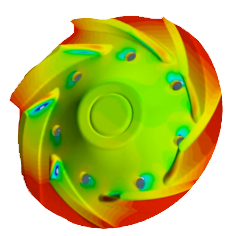

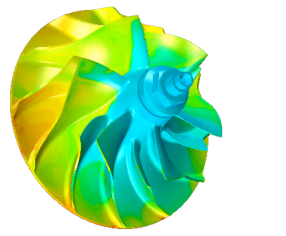

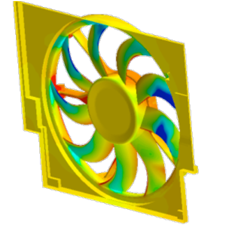

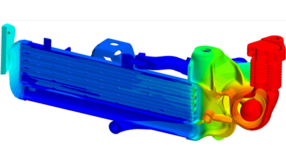

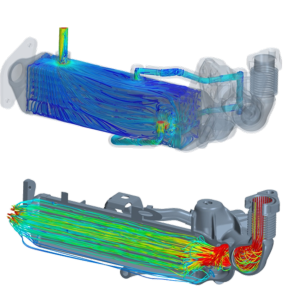

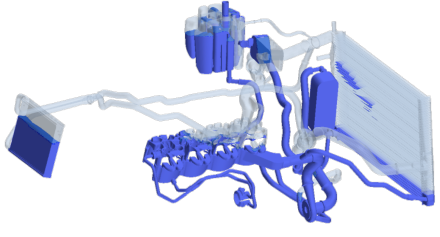

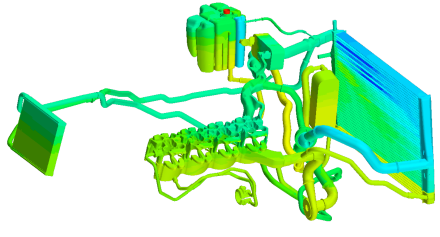

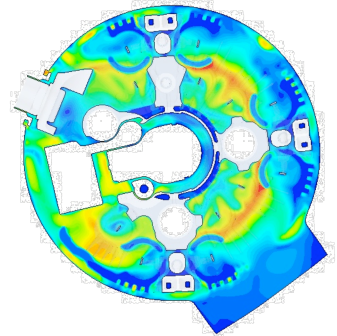

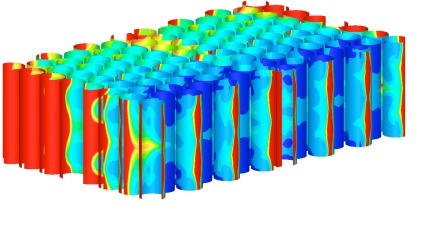

It is a matter of time that virtual testing will substitute physical testing. Not only it proves to be more time and cost efficient it is adding more value to the test procedure as additional information can be retrieved which is not accessible for physical testing: Where is cavitation generated in a water pump? Where does boiling occur in an EGR cooler? Which edge inside the component generates the highest pressure loss?

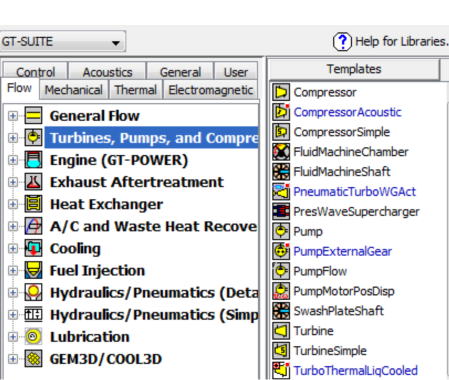

And beyond performance and functional testing the 3D simulation models can further exploited to extract 1D objects for your system simulation, e.g. in GT-SUITE. Whether it is pumps, compressors, fans or heat exchangers our specialized post processing generates 1D objects with performance maps, pressure losses or Nusselt correlations.